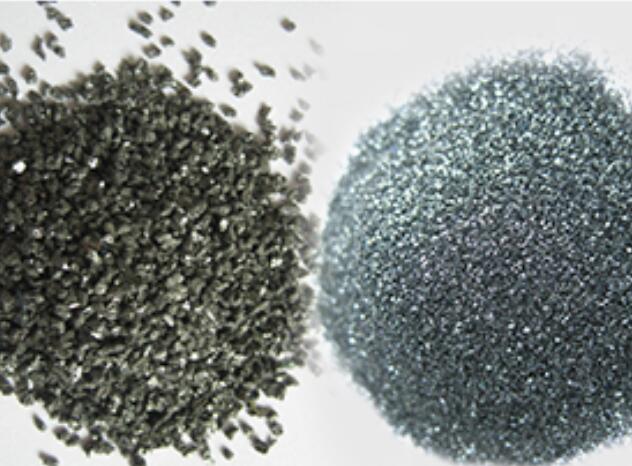

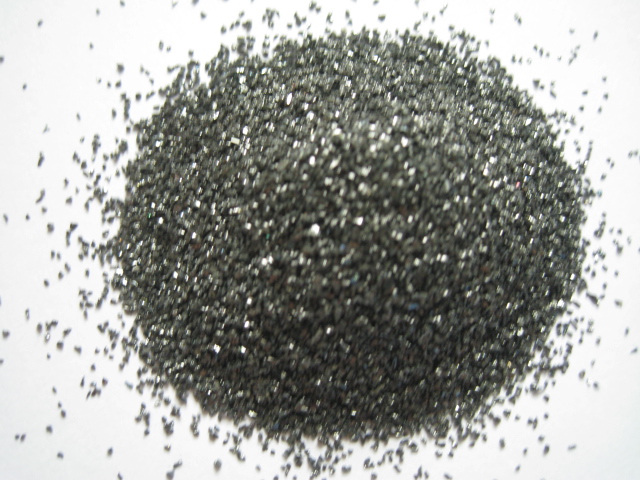

Black Silicon carbide

Product Description:

Black silicon carbide is produced at high temperature in an electric resistance type furnace with quarts sand and petroleum coke as its main raw materials. Its hardness is between fused alumina and synathetic diamond. Mechanical intensity of it is higher than fused alumina. it is brittle and sharp and has electrical and heat conductivity in some degree.

Chemical analysis:

Specification |

Chemical Composition(%) | ||||

| SIC(min) | F.C(max) | Fe2O3(max) | H2O(max) | ||

Grit |

8#-220# | 98 | 0.2 | 0.2 |

1 |

Micro powder |

240#-10000# | 97 | 0.3 | 0.2 | 1 |

Physical characteristics:

| color | black |

| Mohs Hardness | 9.15 |

| Melting point | 2250℃ |

| Maximum service temperature | 1900℃ |

| Real density | 3.2-3.4g/cm3 |

| Microhardness | 2840-3320kg/mm2 |

purpose:

1. Sic can be used in fire-resisting materials and the electronic

2. Reusable abrasive

3. Lapping and polishing medium

4. Grinding wheels and grinding medium

5. Wear-resistant and refractory products

Model:

|

properties Type |

Grains |

|

| 8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220# | ||

| Micro powder | FEPA | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 |

| JIS | #240 #280 #320 #360 #400# #500 #600 #700 #800 #1000 #1200 #1500 #2000 #2500 #3000 #4000 #6000 #8000 #1000 | |